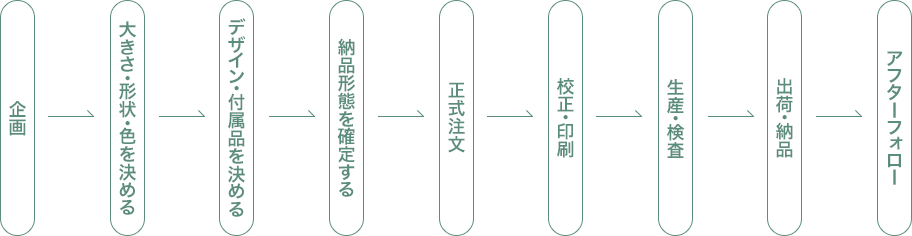

From order to delivery

plan

First, think about the image of the tube you want to make. "Something with a luxurious or flashy image," "something simple or inexpensive or something with an unusual shape that makes an impact," "I want to put hand cream or beauty serum in it," etc.

If you have no idea what to decide, don't worry.

If you consult with our sales staff, we will help you choose the right tube from scratch.

Decide on the size, shape and color

Once you have decided on the image of the tube you want to make, first consider the combination of the diameter (tube diameter) and shoulder length (tube length) based on the capacity.

Next, decide on the shape of the tube. The most distinctive feature is the shape of the tip (screw end). Contents such as hand cream, hair color, and lip balm come in a variety of tip shapes depending on the purpose and occasion of use. Finally, decide on the color of the tube. Decide on your preferred color based on the actual color sample or color chip.

Decide on the design and accessories

Decide on the printing design. The printing method for the tube surface can be silk screen printing, offset printing, hot stamping (foil stamping), etc., and the number of colors that can be printed will vary depending on the printing method.

Also, tubes always need caps to close them. Caps come in a variety of shapes, including screw-type and one-touch types, and they can also be colored or customized. Consider the design of the packaging box and other items.

Determine delivery method

You also need to decide on the delivery method, such as "delivering the tube and cap in separate packages" or "delivering the tube with the cap attached to the open bottom." Since filling methods differ depending on the factory, you will need to discuss in advance with the factory what delivery format you will use.

Official order

Once the final specifications have been decided, please send two instructions to VESSEL JAPAN.

(1) Order form (final specifications, quantity, desired delivery date)

(2) Submitting printing data

Once these two instructions are ready, production can be arranged at the factory.

Proofreading/printing

The submitted printing data will be processed as plate-making data. The factory will send you the final confirmation data, which will be checked (proofread) at this point. Now, everything is ready for production.

The production of plastic tubes begins with making cylindrical fabric. A tube with the specified diameter is formed and then cut to the specified shoulder length.

Finally, the formed tube is printed. This is done carefully to prevent damage to the tube material and print, and to create a glossy finish that gives a beautiful appearance.

Production and Inspection

Finished tubes are shipped from various factories both in Japan and overseas. When the tubes arrive at the logistics center, they are processed by the receiving and shipping staff, and then temporarily stored in a warehouse to await inspection.

After sampling and air blowing, workers inspect each product carefully in a clean room. Only products that meet strict quality standards are approved.

Shipping and delivery

Boxing and packaging are carried out in dedicated clean rooms separate from inspection, and we take great care to prevent dust from adhering to the products.

Products that pass strict inspection standards are shipped to customers. We ask that our transporters always handle them with care. The finished tube containers are delivered to our customers.

Finally, the tubes are filled with the contents, and the product is completed and distributed to the market.

After-sales support

At VESSEL JAPAN, we strive to ensure that our customers are not inconvenienced after receiving our products. We are flexible in responding to any reorders or changes to specifications.